LILOLINK

Our flagship product suite, Lilolink, is an advanced predictive maintenance system engineered to enhance the reliability and efficiency of industrial equipment. Designed to perform seamlessly in both aboveground and underground environments, Lilolink ensures early fault detection and enables proactive maintenance for mission-critical industries.

The Lilolink MachSense line is tailored to address diverse industrial needs with two distinct variants:

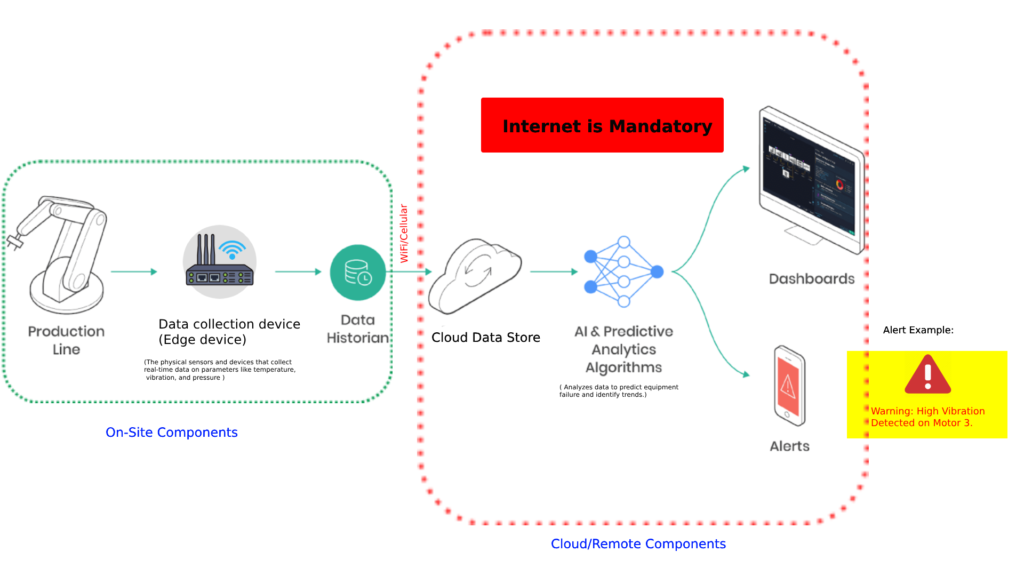

MachSense Cloud: Utilizes cloud-based analytics for real-time monitoring in connected environments, delivering unparalleled insights and efficiency.

MachSense Edge: Operates entirely offline with Edge AI technology, ensuring reliable and secure predictive maintenance in remote or challenging locations.

Both variants empower industries to optimize equipment performance, minimize downtime, and maintain operational excellence.

1 . MachSense - Cloud

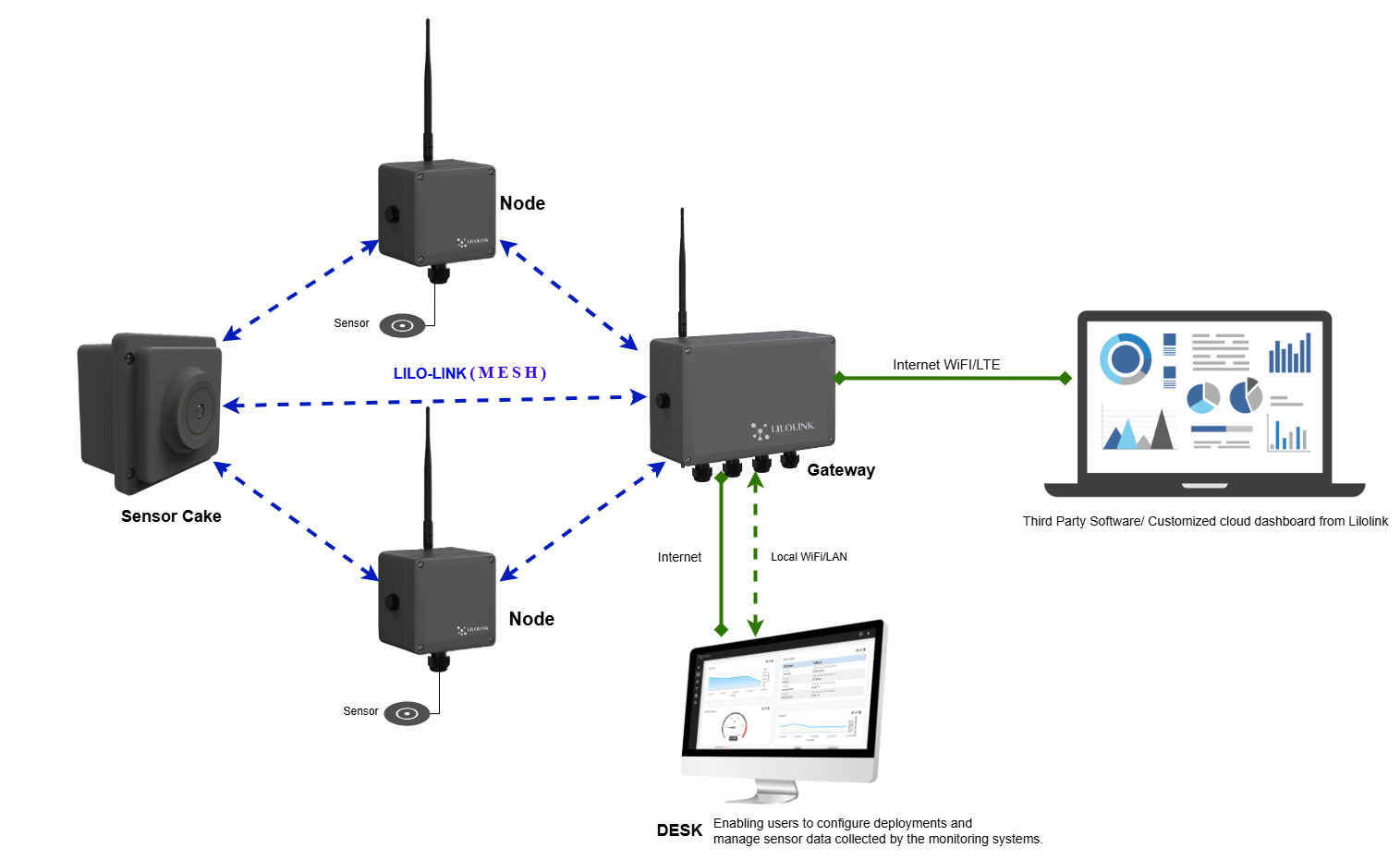

LILOLINK-Gateway (GW)

The LILOLINK-Gateway is the central device that coordinates the entire LILOLINK data acquisition system. It collects sensor data from the Nodes and processes it, pushing the data to your chosen software platform for analysis and recording. The Gateway also allows for two-way communication, enabling configuration updates, such as sampling frequency adjustments, to be sent to the Nodes

LILOLINK-Nodes

LILOLINK-Nodes monitor various sensors deployed at work sites. Our Nodes support a wide range of industrial sensors and brands. They feature long battery life, the ability to create long-range mesh networks, and can transmit data over long distances, both above and below ground, ensuring reliable performance in diverse environments.

LILOLINK-Sensor Cake (SC)

LILOLINK-Sensor Cake (SC) is a versatile device equipped with multiple sensors for various applications. The LILOLINK SC can communicate directly with the LILOLINK-Gateway or through the LILOLINK-Node mesh network, providing flexibility and comprehensive monitoring solutions.

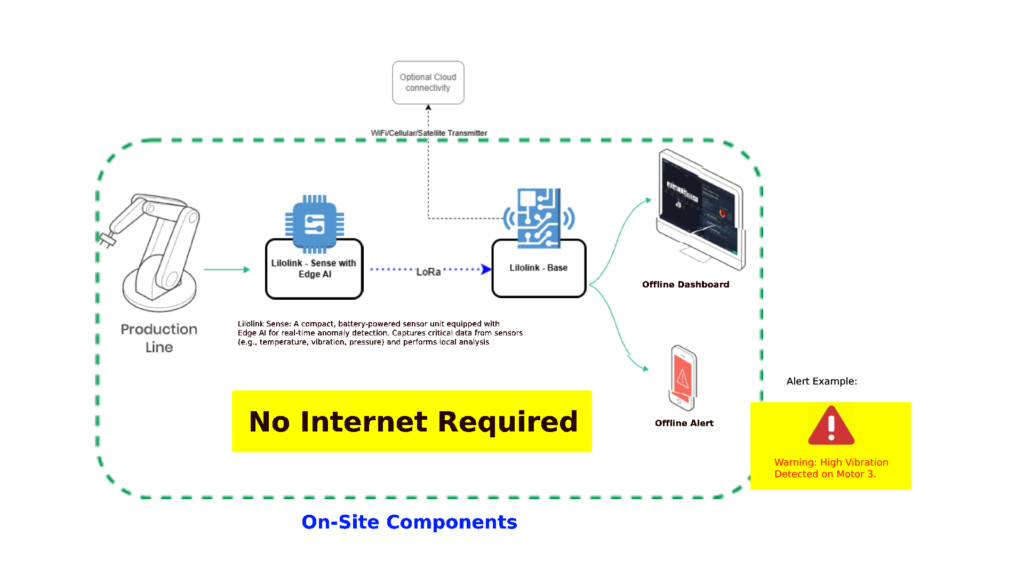

2 . MachSense - Edge

MachSense-Edge is a fully offline predictive maintenance device engineered for remote and challenging environments where internet connectivity is limited or unavailable. Utilizing Edge AI technology, it processes data directly on-site, delivering real-time monitoring and early fault detection without relying on external networks. Its rugged, battery-powered design ensures durability and longevity, making it suitable for harsh conditions. Lilolink Edge empowers operations to maintain optimal equipment performance and reduce downtime, even in the most isolated locations.